What suspension is suitable for my trailer?

- Photos: BPW

- Date: 10.07.24

For many motorists, air suspension is considered pure luxury. Here, not only Rolls Royce, Bentley and Mercedes S-Class drivers travel on air, but also Euro pallets, fresh concrete, fish fingers and even iron ore. However, the fact that trailers today are equipped with air suspension even for the toughest off-road use has nothing to do with luxury: air absorbs shocks and vibrations better than steel suspension. As the interface between running gear and superstructure, air suspension ensures safe driving with any load and protects the driver as well as the transported goods, vehicle, tyres and roads. Height adjustment of the trailer by releasing the air enables flexible adaptation to loading ramps. Air suspension plays a central role in axle load control, right through to the fuel-saving lifting of individual axles. This means that every load arrives at its destination safely and undamaged, no matter how fragile or heavy it is. The variety of air-suspended vehicle types is fascinating: tippers, refrigerated boxes, curtainsiders, tank bodies or low loader trailers; no two trailers are the same. This means that the design of running gears is a challenge. In addition to the respective transport requirements, the individual concepts of vehicle manufacturers and customer specifications increase the complexity and diversity of variants. At the same time, economic pressure is increasing: standard trailers and specialised vehicles must be equally efficient in terms of ability to design, assemble, operate, maintain and repair.

Standard trailers and specialised vehicles must be equally efficient in terms of ability to design, assemble, operate, maintain and repair.

While this may sound like an insurmountable challenge, BPW has found an intelligent solution. A modular concept allows almost unlimited combinations of the number of axles and axle types, air suspension, ride heights, tyre sizes and other parameters. Innovations in digitalisation, metallurgy, vehicle production, telematics and the use of AI make the trailer more unique and more efficient than ever before. I am often asked how I, as a product manager at BPW, keep track of everything, as the possible combinations of all running gear elements run into the billions. It amazes many people that this wide range of variants can be represented by just three different running gear systems. One of these, with our SL air suspension, is designed for heavy vehicles between 12-14 tons, i.e. for special applications such as mining. It's a fascinating subject, but today I will focus on the more common axle loads between 9 and 12 tons.

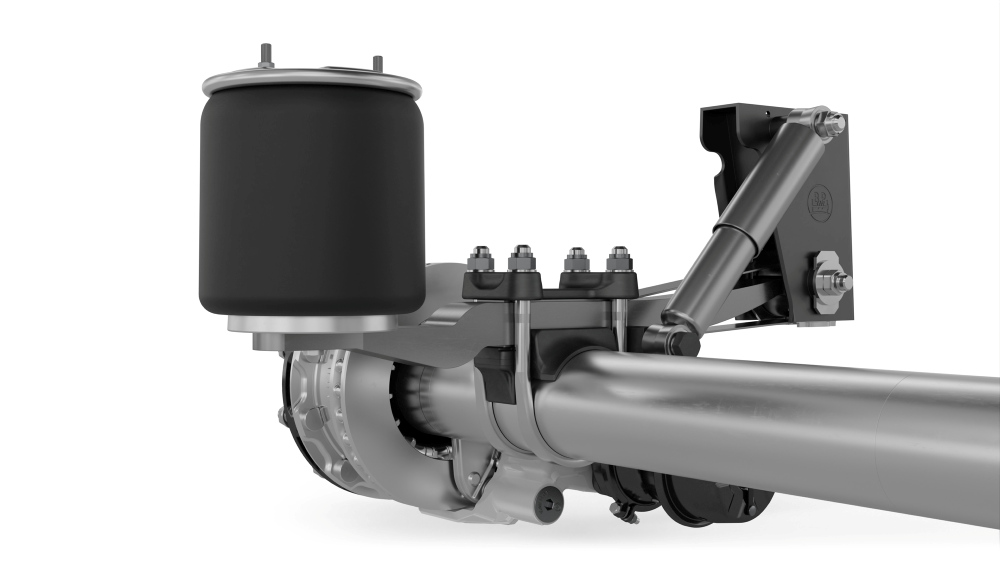

ECO Air

ECO Air is our robust solution for on-road and light off-road use and was developed for an axle load of 9 tons – typical for the standard segment, which includes curtainsiders, dry and refrigerated boxes, tippers and sliding floor trailers. All components have been trimmed for minimum weight and maximum ease of maintenance - saving a massive 27 kilograms on the three-axle vehicle. A patent-pending laser process enables us to clamp the ECO Air air suspension to a round axle beam for the first time. This means that it not only can be disassembled, but can also be serviced as required thanks to replaceable individual components.

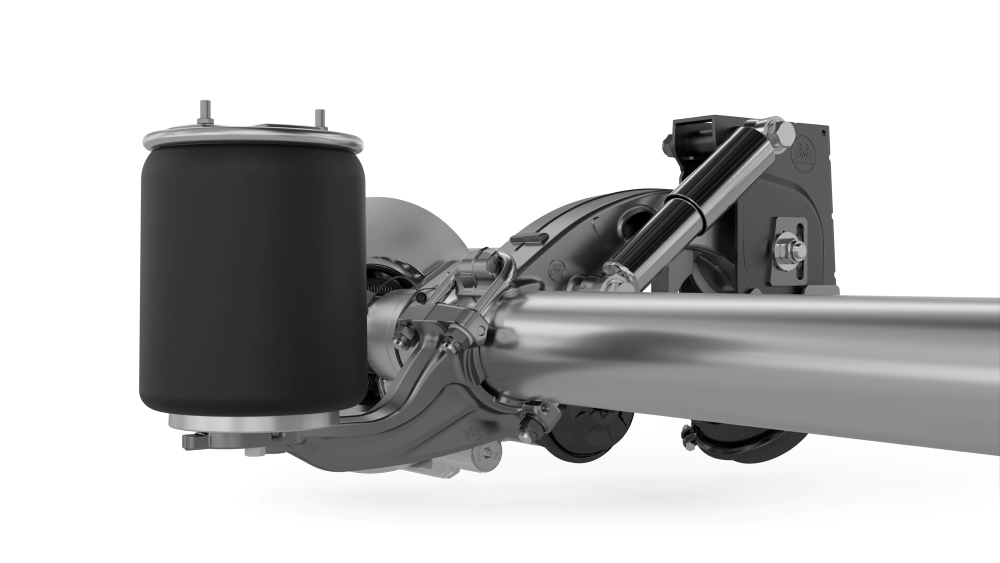

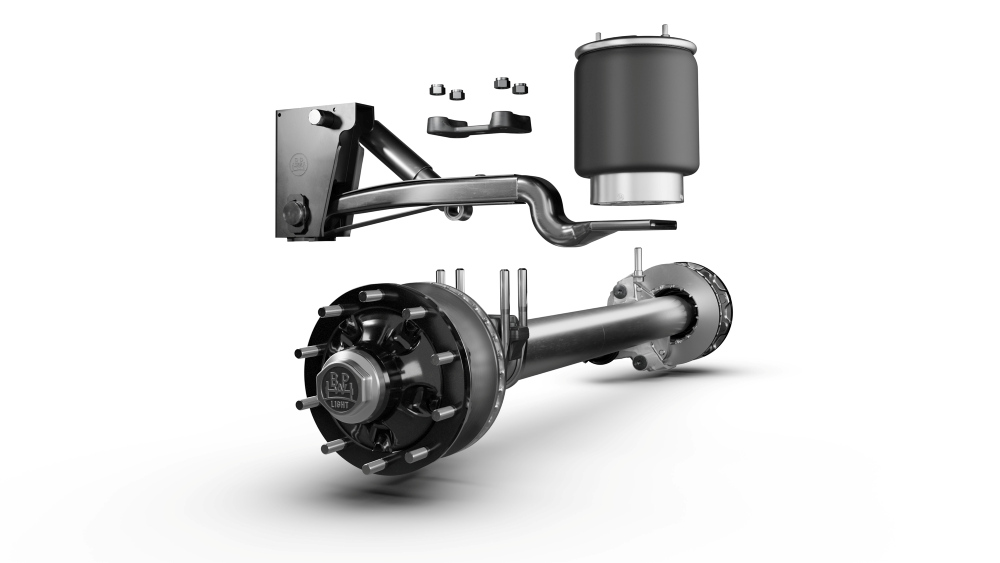

Airlight II

Airlight II is BPW's all-rounder, with which practically any conceivable configuration between 9 and 12 tons can be realised: from near-standard trailers to customised special vehicles, from lightweight construction to heavy-duty off-road use. The variety of Airlight II variants is hard to beat: whether tanker and silo vehicle, megatrailer, swap body, low loader trailer or vehicle and wood transporter – everything is possible.

And Airlight II is also available with lightweight options. This allows additional usable load to be transported, especially for weight-sensitive applications. An optional trailing arm and an aluminium hub reduce vehicle weight and increase the load by 96 kilos. This makes Airlight II with lightweight options the lightest trailer running gear on the market. This noticeably increases efficiency, not only for liquid and bulk goods.

The two systems overlap in the 9-ton segment. For this reason, vehicle operators are sometimes faced with the question as to whether it is better to order their new vehicle with ECO Air or Airlight II running gear. We are happy to advise you here: in a personal consultation, together we can analyse your fleet, driving profiles, the planned ownership period of the vehicle and personal preferences. But given the diversity of the industry, here is an orientation aid: the more unique the trailer, the more in favour of Airlight II. Airlight II is therefore unbeatable for specialised vehicles. A combination of Airlight II and the lightweight construction package is ideal for tankers and silo vehicles. When it comes to curtainsiders or dry / refrigerated boxes, there is a lot to be said in favour of ECO Air. Nevertheless, some vehicle operators with mixed fleets and their own workshops decide to equip all trailers uniformly with Airlight II: this further rationalises maintenance and spare parts management.

The intelligent trailer of the future becomes reality

Anyone who also wants to avoid unplanned downtimes and reduce operational costs in vehicle operation cannot ignore an innovation: iC Plus. A new suspension generation based on a 9 t unit with pre-assembled brake pad wear sensor, disc or drum brakes and ECO Air or Airlight II air suspension, combined as standard with transport telematics from idem telematics.

This may not sound spectacular, but in combination with AI-supported maintenance management and tools such as the digital maintenance calendar, for the first time BPW and idem telematics are enabling needs-based fleet and smart maintenance management. For example, artificial intelligence recognises deteriorating brake performance before it can cause a failure. One of the amazing features of the iC Plus suspension generation is also axle load detection, which makes for transparent utilisation of the vehicle. Drivers, fleet managers and dispatchers can now use the Cargofleet 3 telematics portal to see whether the trailer is too heavy – or too empty – in real time. If required, iC Plus can also control and network the AirSave tyre pressure regulation system, which not only monitors the tyre pressure but also regulates it fully automatically. All information is collated in Cargofleet 3, which also maintains a digital maintenance calendar and a digital vehicle file in the Cloud and reminds users of upcoming workshop appointments.

Whether you opt for ECO Air, Airlight II or iC Plus: BPW makes the complex Vehicle and fleet management easy and more efficient than ever. As a first step towards economically optimised trailer operation, I recommend that you arrange a consultation with BPW: this is free of charge, without obligation – and has already helped many vehicle operators to make enormous savings. Not just in terms of time and money: trailers with typical BPW reliability are stress-free and keep your head clear. And that is also worth a lot in itself!